Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

In the automotive industry, precision is everything, especially when it comes to car seat production. How can you ensure every cut of leather is perfect for fit, comfort, and durability? The answer lies in using the Premium leather cutting machines.

In this article, we'll explore how leather cutting machines revolutionize car seat production, making the process faster, more efficient, and more accurate. You'll discover key features, challenges, and benefits of investing in high-quality leather cutting equipment.

Leather comes in various types, including genuine leather and synthetic leather. Genuine leather, being a natural material, often varies in texture, thickness, and elasticity, posing challenges in achieving consistent cuts. This variability is one of the main reasons manual cutting methods are less reliable. Synthetic leather, while more uniform, can be challenging due to its lack of flexibility. It behaves differently than natural leather, which requires adjustments in cutting techniques to achieve clean edges. Each type of leather requires different handling and cutting techniques, making it crucial to use a leather cutting machine that can adapt to these variations.

Additionally, automotive interiors go beyond seats—they include steering wheels, dashboards, and door panels, each requiring different types of leather materials with varying thickness, texture, and flexibility. The cutting machine must be adaptable to these differences to ensure that all components, whether a seat, steering wheel, or dashboard, fit perfectly and maintain high-quality standards.

The automotive interior industry requires precision cutting to ensure all components, including car seats, steering wheels, dashboards, and door panels, fit perfectly. A slight deviation in the cutting process can lead to poor-quality finishes, affecting the overall aesthetics, durability, and comfort of the vehicle. This makes precision a critical factor in automotive leather cutting, which is Premium achieved through advanced technology. Modern leather cutting machines, particularly those equipped with CNC technology, offer the ability to cut with extreme precision, reducing the risk of errors and ensuring each leather piece meets exact specifications.

With the increasing demand for high-quality custom interior designs, the need for machines that can produce consistent results in every run has never been greater. The ability to cut leather for steering wheels, dashboards, and seats with precision ensures that all parts of the interior look and feel cohesive.

Leather is prone to natural defects such as scars, wrinkles, and holes, all of which can compromise the quality of the cut and the final product. These defects can occur naturally during the tanning process or from the hide itself. Modern leather cutting machines, especially those integrated with advanced scanning technologies, can detect and avoid these defects by analyzing the leather's surface and adjusting the cutting patterns accordingly. This reduces waste, improves material utilization, and ensures that only the Premium parts of the leather are used for production.

Machines equipped with defect-detection systems can significantly enhance production quality, preventing costly mistakes and unnecessary material waste, which is especially crucial when working with high-cost automotive leather.

One of the standout features of the Premium automotive leather cutting machines is the use of advanced cutting tools, such as oscillating knives. These tools are designed to cut leather cleanly, preventing fraying and ensuring smooth, precise edges. Oscillating knives are particularly effective at cutting through thick or tough materials, making them ideal for automotive leather applications. Unlike traditional manual cutting methods, oscillating knives provide superior control and precision, ensuring high-quality cuts that are consistent and repeatable.

For larger leather pieces, such as those used in dashboards or steering wheels, opt for a machine with multiple cutting tools to improve cutting speed and reduce downtime. The ability to switch between different cutting tools automatically allows for a more streamlined process, especially in high-volume production environments.

Modern leather cutting machines are equipped with CAD (Computer-Aided Design) software integration. This allows manufacturers to create detailed digital patterns, which are then automatically transferred to the cutting machine. The integration of CAD software not only improves accuracy but also enhances the flexibility of design, enabling manufacturers to quickly adapt to new designs or custom orders without requiring physical pattern creation. CAD integration ensures that the design is transferred directly into the machine, minimizing errors and reducing the need for manual adjustments during the cutting process.

This capability enables faster prototyping and quicker adaptation to changes in customer preferences or market trends, making it a crucial feature for businesses focused on innovation in automotive interior design.

Efficiency in leather cutting is crucial, especially in large-scale production. The Premium car seat and automotive leather cutting machines utilize intelligent nesting software, which arranges cutting patterns in a way that minimizes waste and maximizes material usage. By optimizing the layout, these machines ensure that every square inch of leather is utilized, leading to significant material cost savings over time.

By maximizing material usage and reducing the amount of waste generated, these machines contribute to a more sustainable manufacturing process. This not only helps lower production costs but also reduces the environmental footprint of leather cutting operations, especially for the leather pieces used in large-volume car seat and interior production.

CNC (Computer Numerical Control) leather cutting machines are much faster than manual cutting methods. While traditional methods can only handle a limited number of cuts per hour, CNC machines can process hundreds of pieces in the same timeframe. This speed increase is crucial for meeting the high demand in automotive interior production, allowing manufacturers to produce more seats, steering wheels, dashboards, and other components in less time. The efficiency gains offered by CNC machines allow businesses to fulfill orders faster and maintain a competitive edge in a fast-paced market.

Speed can significantly improve production rates, but always ensure the machine maintains its cutting quality for optimal results. Faster cutting speeds should never come at the expense of precision, as this can lead to costly errors and wasted materials.

Leather cutting traditionally relied heavily on skilled labor, which often required years of experience. CNC leather cutting machines reduce this reliance by allowing operators to control the machine with basic training. This not only cuts down on training costs but also helps manufacturers maintain production even when skilled labor is scarce. With automated systems in place, fewer highly skilled workers are needed to oversee the cutting process, freeing up resources for other areas of production.

This reduction in reliance on skilled labor can also help businesses scale more easily and reduce the risk of production delays caused by labor shortages.

One of the greatest advantages of using the Premium car seat and automotive leather cutting machines is their ability to produce consistent cuts every time. Unlike manual cutting, where human error can lead to inconsistencies, CNC machines provide the same quality cut for every leather piece. This repeatability is essential for maintaining the high standards expected in automotive interiors. Whether it's a standard pattern or a custom design for a steering wheel, dashboard, or seat, these machines ensure each leather piece is cut to the exact specifications, eliminating variation that could compromise the final product.

Maintaining consistency in production is critical, especially for large-scale manufacturing where even small variations can lead to significant quality control issues.

| Model | Cutting Speed | Cutting Tools | Key Features | Premium For |

|---|---|---|---|---|

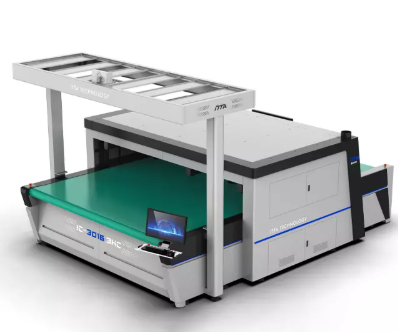

| ITTA-IC3016-3HC | High | Oscillating Knife | CAD integration, high precision | Small to medium cuts for car interiors (e.g., dashboards, steering wheels) |

| ITTA-IC800C | Medium | Single Cutter Head | Affordable, simple design | Custom orders and small businesses |

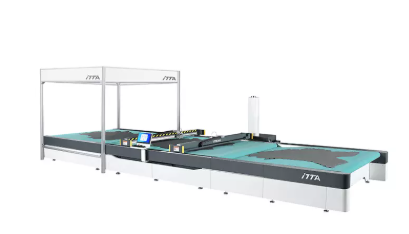

| ITTA-IC980DHC | High | Oscillating Knife | Intelligent nesting, defect detection | Large volume production of car seats and automotive leather |

The ITTA-IC3016-3HC is an excellent choice for manufacturers looking for precision and efficiency. This model offers high-speed cutting with an oscillating knife system that ensures smooth and precise edges for car seat leather, steering wheels, and dashboards. It also features advanced software integration that makes it compatible with various CAD designs, allowing for a seamless production workflow. With its robust design, the ITTA-IC3016-3HC is well-suited for applications requiring multiple smaller cuts, such as dashboards and steering wheels.

The ITTA-IC800C is perfect for smaller-scale or specialized leather cutting projects. Its single-cutter head design allows for precise cuts, making it ideal for custom orders or unique car seat designs. This model balances simplicity and reliability, providing an affordable yet high-quality solution for smaller businesses that need a dependable, cost-effective leather cutting machine.

The ITTA-IC980DHC combines intelligent nesting and automated material handling, significantly improving efficiency. With its advanced scanning and defect-detection features, this machine optimizes material usage and ensures only the highest quality parts of the leather are used for production. It’s a smart choice for manufacturers looking to enhance both quality and production speed, especially for large-scale car seat production.

Before purchasing a leather cutting machine, it’s essential to assess your workspace size and production needs. Machines come in various sizes, and choosing the wrong size can limit your workspace or result in inefficient use of your production area. Ensure that the machine you choose fits comfortably within your facility while meeting your production volume requirements. Having a machine that is appropriately sized for your space can also help improve workflow and reduce the time spent on material handling.

Different types of leather, such as soft leather or thick hides, require different cutting approaches. Choose a cutting machine that can accommodate a wide range of leather thicknesses to ensure versatility in your production. For car seat production, where thick hides are common, selecting a machine capable of handling heavy materials is crucial. This flexibility will allow you to diversify your product offerings and meet customer demands for different leather styles.

Look for leather cutting machines with advanced automation features like intelligent nesting software and CAD integration. These features not only improve the precision of cuts but also streamline the overall production process by reducing manual intervention and errors. Automated systems also provide greater control over production schedules, helping manufacturers meet deadlines and optimize output.

| Feature | Manual Cutting | CNC Leather Cutting Machine |

|---|---|---|

| Cutting Speed | Slow, limited cuts/hour | Fast, hundreds of cuts/hour |

| Material Waste | High | Low, optimized with nesting |

| Precision | Inconsistent, prone to error | High precision, ±0.1mm accuracy |

| Labor Requirement | High, skilled labor needed | Low, basic training required |

| Cost Efficiency | High operational cost | Low operational cost in the long term |

| Customization Flexibility | Limited, requires physical patterns | High, can adapt to new designs easily |

CNC leather cutting machines offer significant advantages over traditional methods. With their ability to handle more cuts in less time, these machines can drastically reduce labor costs while increasing production output. This makes them a more cost-effective option for businesses looking to scale their operations without compromising on quality. Over time, the initial investment in CNC technology pays off through improved efficiency and reduced waste.

Manual cutting processes often result in high material waste due to inefficient pattern arrangement. In contrast, CNC leather cutting machines use intelligent nesting software that optimizes the layout, ensuring that every piece of leather is used efficiently. This leads to reduced waste and lower material costs, making CNC machines an environmentally friendly and cost-effective solution.

CNC machines provide a level of precision that is impossible to achieve with manual cutting. With accuracy levels as fine as ±0.1 mm, CNC leather cutting machines ensure every car seat component is cut to exact specifications. This precision is crucial for maintaining the quality and durability of automotive interiors. The consistency offered by CNC machines also helps improve the overall quality of the finished product.

Choosing the Premium car seat leather cutting machine is crucial for improving production efficiency and product quality. Advanced CNC machines, like those from ITTA, offer superior precision, faster cutting speeds, and reduced material waste. These benefits make them an excellent investment for automotive interior production.

For businesses aiming to scale while maintaining high-quality standards, ITTA’s models provide the perfect solution. By investing in a high-quality leather cutting machine, manufacturers can enhance both efficiency and product quality.

When selecting a leather cutting machine, ensure it fits the specific leather types and production volume your business requires.

A: A leather cutting machine is a computer-controlled tool used to cut leather with precision. It ensures accurate, clean cuts for various applications, including car seats, furniture, and accessories.

A: A car seat leather cutting machine offers higher precision, faster cutting speeds, and reduced material waste, making it a more efficient and cost-effective solution compared to manual methods.

A: CNC leather cutting machines provide superior accuracy, consistency, and scalability, which are essential for producing high-quality car seat leather with minimal waste.

A: The cost of a leather cutting machine varies depending on the model, features, and production capacity. Advanced machines with automation and CAD integration typically range from a few thousand to tens of thousands of dollars.

A: A car seat leather cutting machine uses intelligent nesting software to optimize pattern placement, minimizing offcuts and ensuring maximum material utilization.