Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

In the automotive industry, precision matters—especially when working with luxury materials like leather. How can manufacturers ensure leather components meet high standards while keeping costs low?

In this article, we’ll explore how Leather Cutting Machines revolutionize automotive production. You’ll learn how these machines enhance speed, accuracy, and material efficiency, helping businesses stay competitive.

An industrial leather cutter for car interiors is a machine designed to cut leather into precise shapes and patterns required for automotive applications. These machines typically use CNC (Computer Numerical Control) technology, which allows for digital designs to be executed with high accuracy. The ability to handle complex, high-precision cuts makes them ideal for intricate automotive interior components such as seat upholstery and dashboard panels.

By utilizing Leather Cutting Machines, manufacturers can automate the cutting process, reducing the reliance on skilled labor and minimizing human error. The CNC system controls the cutting head, which can be a knife or a laser, to ensure that each piece is cut according to the exact specifications needed for automotive interiors. This precise control of the cutting head also allows for more flexibility in design, providing manufacturers the ability to produce unique and custom leather pieces.

Manual leather cutting, though effective in smaller-scale operations, has limitations in terms of precision, speed, and material utilization. These challenges can lead to wasted time and material, which is particularly costly in industries like automotive manufacturing, where leather can be expensive. By switching to CNC leather cutting technology, manufacturers can achieve several key benefits:

Higher Material Utilization: CNC machines can optimize the layout of patterns, minimizing waste and maximizing the use of expensive leather. By accurately mapping the patterns onto the leather hide, manufacturers can significantly reduce material costs over time.

Enhanced Production Speed and Consistency: Automated cutting ensures consistent results, reducing the time spent on manual adjustments and improving overall productivity. This consistency is critical in mass production, where variations in quality can result in higher rejection rates or costly rework.

To improve material utilization, it is beneficial to invest in machines with advanced nesting software. This software arranges patterns more efficiently, further reducing waste and enhancing the overall cost-effectiveness of production.

Below is a comparison between CNC leather cutting and traditional manual cutting, highlighting key advantages in terms of material utilization, speed, and consistency.

| Criteria | CNC Leather Cutting | Traditional Manual Cutting |

|---|---|---|

| Material Utilization | 85% - 92% utilization | 70% - 80% utilization |

| Production Speed | Faster, higher volume | Slower, limited by labor |

| Consistency | High, precise cutting | Varied, dependent on skill |

| Labor Dependency | Low, automated process | High, skilled labor required |

| Edge Quality | Clean, no fraying | Risk of uneven edges |

| Cost Efficiency | Long-term savings (due to reduced waste and labor costs) | Higher due to material waste and labor costs |

Before the cutting process begins, digital designs are created using CAD (Computer-Aided Design) software. These digital files are then fed into the leather cutting machine. This process ensures that each leather piece is cut according to precise specifications, eliminating the need for manual adjustments and minimizing human error. CAD allows manufacturers to visualize how the finished pieces will look, helping to identify any potential issues before production begins.

Once the design is finalized, the Leather Cutting Machine can begin the process of cutting the leather. The ability to create digital designs makes it easier to modify and replicate patterns, allowing manufacturers to produce leather components quickly and consistently. These machines can accommodate intricate designs and multiple layers of leather, increasing production flexibility and enabling the creation of custom pieces when needed.

The table below summarizes the key steps in the leather cutting process:

| Step | Description | Key Benefit |

|---|---|---|

| Step 1: Design Creation | CAD software is used to create precise leather patterns. | Ensures accurate specifications and customization. |

| Step 2: Material Preparation | Leather is carefully laid flat and aligned on the cutting bed, ensuring smooth and wrinkle-free material. | Prevents distortion, ensuring proper alignment and consistency before cutting. |

| Step 3: Intelligent Nesting | Software arranges patterns to maximize leather utilization. | Reduces material waste and optimizes usage. |

| Step 4: CNC Precision Cutting | The machine uses oscillating knives or rotary cutters to cut leather based on the pre-designed patterns. | High precision, clean edges, and smooth cuts. |

| Step 5: Quality Inspection | Finished pieces are inspected for defects and quality. | Guarantees product consistency and quality. |

Nesting is the process of arranging the cutting patterns on the leather hide in the most efficient way possible to maximize the use of the material. Advanced nesting software uses algorithms to place patterns in the available space, ensuring that leather is used efficiently while minimizing waste. This is particularly important when working with expensive materials like leather, as even small reductions in waste can lead to significant cost savings over time.

By using car interior leather cutting machines with intelligent nesting capabilities, manufacturers can optimize material usage, reducing costs associated with leather waste. Additionally, intelligent nesting software can adjust for flaws in the leather, such as defects or inconsistent thickness, ensuring that each pattern is cut precisely. This software helps reduce the reliance on manual labor and enhances production efficiency by automating the arrangement of patterns.

The cutting precision of CNC leather cutting machines is essential for achieving high-quality automotive interior components. With the use of oscillating knives or rotary cutters, the leather is cut with precision, creating clean edges without fraying. This level of accuracy ensures that each piece of leather fits perfectly in its designated position, whether it’s a seat cover or a door panel.

This ensures that each piece of leather meets strict quality control standards, preventing defects from affecting the final product. Furthermore, CNC machines can handle complex patterns and intricate designs that would be difficult to achieve with manual cutting methods. Ensuring that the Leather Cutting Machine has the ability to cut leather of varying thicknesses is essential to accommodate different types of automotive components, from thick seat covers to delicate trim pieces.

Leather is commonly used in automotive seats, steering wheels, and door panels due to its durability and aesthetic appeal. Precision cutting is crucial to ensuring that each component fits seamlessly into the car’s interior, enhancing both the appearance and comfort of the vehicle.

Leather Cutting Machines are equipped to handle the specific requirements of automotive interior components. Whether it's cutting intricate designs for seat upholstery or ensuring the right thickness for steering wheel covers, these machines offer the precision and flexibility needed. The advanced cutting capabilities ensure that each leather piece maintains its integrity and high-quality appearance throughout the production process.

In addition to seats and steering wheels, leather cutting machines are also used to produce other automotive interior components, such as floor mats, trunk liners, and sunshades. Each of these parts requires a specific cutting method to ensure they fit perfectly and maintain the desired quality and durability.

With the versatility of car interior leather cutting machines, manufacturers can easily switch between different automotive components, reducing production times and improving overall efficiency. Whether producing high-end leather goods for luxury vehicles or more utilitarian components for mass-produced cars, these machines provide the flexibility required to meet diverse production needs.

When choosing a leather cutting machine, it's essential to consider the size of the machine and the workspace available. The machine should fit comfortably in your production area without overcrowding the space or limiting mobility. Overly large machines can disrupt workflow, while smaller machines may not be able to accommodate large leather hides.

Moreover, the machine must be capable of handling the dimensions of the leather pieces you intend to cut. Ensuring that the Leather Cutting Machine can accommodate various sizes will help maximize productivity and flexibility. Machines with adjustable tables or customizable features can offer added convenience in various production environments.

A key factor in selecting the right machine is ensuring it is compatible with the software you use for design creation. The machine should seamlessly integrate with CAD and nesting software to ensure smooth data transfer and optimal pattern arrangements. Having a machine that is easy to set up and use will significantly improve operational efficiency.

Automation features, such as automatic pattern nesting, can save time and reduce the chance of human error. These features allow the machine to adjust settings based on material type, thickness, and cutting requirements, making the entire process more efficient. Advanced machines can also offer real-time feedback on material usage and cutting precision, further enhancing the production process.

To ensure that your leather cutting machine continues to perform at optimal levels, regular maintenance is required. Look for machines that offer easy maintenance options, such as blade replacement and software updates, to extend their lifespan. Preventative maintenance can prevent costly downtime and repair issues in the future.

Choosing a car interior leather cutting machine with long-term support and maintenance capabilities will help reduce downtime and keep production running smoothly. Machines with a strong support network and available spare parts ensure easy maintenance and minimize production disruptions. A good warranty and customer service are also critical to maintaining reliable operations.

While laser cutting machines are popular for various applications, CNC cutting machines are typically preferred for genuine leather. Laser cutting can cause thermal damage, discoloration, and uneven edges, which are undesirable when working with high-quality leather.

CNC cutting uses precision blades that do not generate heat, ensuring clean, smooth edges and maintaining the integrity of the leather’s texture. This makes CNC the ideal method for cutting leather for automotive interiors, where precision and material integrity are essential.

CNC leather cutting machines are designed to provide clean edges with no fraying, ensuring that the finished leather component maintains its quality and appearance. This is particularly important for high-end automotive interiors, where the appearance and durability of leather are critical. The precise nature of CNC cutting allows for superior edge quality, reducing the likelihood of defects and improving overall product consistency. The table below compares the key differences between CNC cutting and laser cutting for leather, illustrating why CNC cutting is the superior choice for automotive interior applications:

| Factor | CNC Cutting | Laser Cutting |

|---|---|---|

| Edge Quality | Clean, smooth edges with no fraying | Risk of burnt, uneven edges |

| Material Integrity | Maintains leather's natural texture | Can cause thermal damage, discoloration |

| Precision | High precision with minimal human error | Less precise, may cause slight deviations |

| Suitability for Leather | Ideal for high-quality leather | Not recommended for genuine leather |

| Heat Generation | No heat generation during cutting | Heat can damage edges and surface |

| Application | Ideal for automotive interiors | Suitable for synthetic or non-leather materials |

By automating the cutting process, Leather Cutting Machines reduce the need for skilled labor. These machines are easy to operate, and even less experienced workers can manage them after minimal training. This significantly reduces the dependency on highly skilled workers, which is especially beneficial in high-volume production settings.

This reduces the dependency on skilled workers, cuts training costs, and increases productivity, allowing workers to focus on other tasks in the production process. The reduction in labor dependency also helps mitigate risks associated with worker fatigue and human error, leading to more reliable production outputs.

CNC leather cutting machines operate faster than manual cutting methods, allowing manufacturers to increase production speed. By optimizing cutting patterns and reducing the need for manual adjustments, these machines can produce leather components in a fraction of the time.

This efficiency is crucial in high-demand environments, where reducing waiting times between production stages can significantly impact the overall output. Considering machines that can handle both small and large production runs provides the flexibility to scale operations according to demand, ensuring manufacturers can meet tight deadlines without sacrificing quality.

The use of Leather Cutting Machines in automotive interior production brings several advantages, such as better material utilization, improved precision, and faster production speeds. Adopting CNC cutting technology helps manufacturers meet the rising demand for high-quality automotive components while minimizing costs and waste. With the right equipment, manufacturers can boost production efficiency and maintain product quality, staying competitive in the industry.

When selecting the right machine, it's important to consider factors like machine size, software compatibility, and maintenance needs. With suitable equipment, manufacturers can enhance production capabilities, reduce costs, and deliver top-quality automotive leather components that meet both consumer and industry expectations.

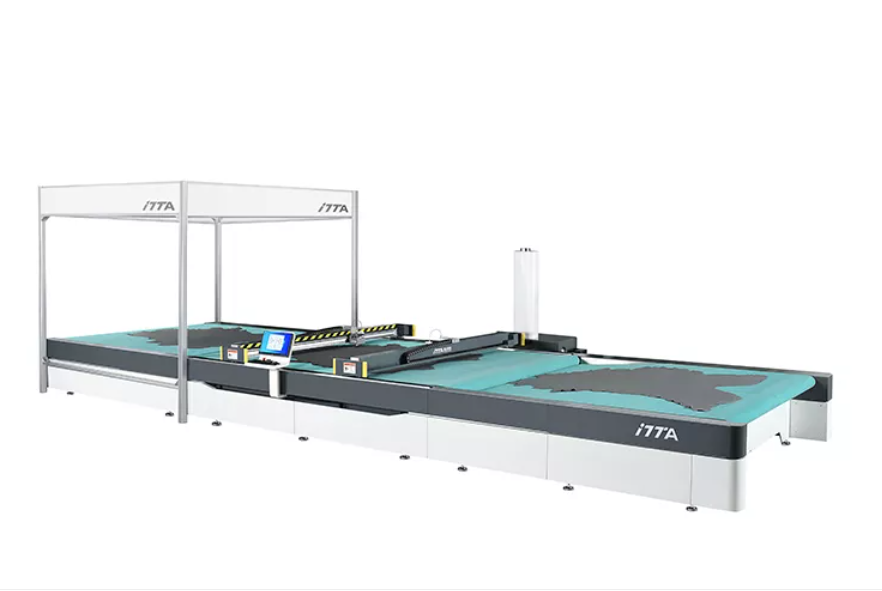

ITTA offers cutting-edge solutions with Leather Cutting Machines that optimize production, reduce waste, and ensure premium leather quality. Their innovative technology provides value to manufacturers by improving efficiency, consistency, and reducing costs in automotive interior production.

A: An industrial car interior leather cutter is a machine designed to cut leather precisely for automotive applications. It uses Leather Cutting Machines equipped with CNC technology to ensure accuracy and efficiency in high-quality leather components for car interiors.

A: A Leather Cutting Machine operates by using CAD software to create digital patterns, which are then fed into the machine. The machine cuts the leather with precision, ensuring high-quality results for automotive seats, panels, and more.

A: CNC Leather Cutting Machines offer superior precision, faster production speeds, and reduced material waste compared to manual cutting. This is essential for achieving high-quality automotive interior components with minimal defects.

A: The main benefits include enhanced cutting precision, reduced labor costs, and improved material utilization. A car interior leather cutting machine can efficiently produce consistent, high-quality parts for automotive interiors, boosting overall productivity.

A: The cost of a Leather Cutting Machine can vary based on factors such as size, technology, and automation features. Prices typically range from several thousand to tens of thousands of dollars depending on the machine’s capabilities and customization.

A: Yes, Leather Cutting Machines are designed to cut various types of leather, including thick and soft hides. This flexibility allows manufacturers to create diverse automotive interior components, ensuring a perfect fit for different materials.

A: CNC cutting provides higher precision, faster speeds, and better material utilization than manual cutting. It also reduces human error, ensuring consistent quality in Leather Cutting Machines compared to traditional manual methods.

A: Regular maintenance for a Leather Cutting Machine includes blade replacement, software updates, and cleaning. Proper care ensures the machine operates efficiently and maintains high cutting precision for automotive interior production.