Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

Leather cutting machines are essential tools for manufacturers who rely on leather as a core material. From fashion and automotive to furniture and footwear industries, precision and efficiency are crucial when producing leather goods. The right leather cutting machine can significantly enhance productivity, improve quality, and reduce material waste.

In this article, we will guide you through the factors to consider when choosing a leather cutting machine that meets your manufacturing needs. Understanding these key considerations will help you make an informed decision and choose the right machine for your business.

When it comes to leather cutting, there are several types of machines available, each offering unique features suited for different manufacturing needs. Choosing the right type of machine depends on factors such as production volume, the complexity of the cuts, and the types of leather you are working with.

Blade-based leather cutting machines utilize rotating or oscillating blades to cut through leather. These machines provide high cutting precision, making them ideal for cutting leather into specific shapes or patterns. The blades move swiftly across the leather surface, ensuring clean and accurate cuts without causing damage to the material.

Advantages of Blade-Based Cutting Machines:

Precision: Blade-based machines offer superior accuracy, ensuring clean cuts with minimal material wastage.

Speed: These machines can cut large volumes of leather in a short time, improving production efficiency.

Versatility: Suitable for various leather types, including soft, hard, and synthetic leathers.

Blade-based leather cutting machines are ideal for industries such as:

Fashion and Apparel: Cutting leather for handbags, jackets, and accessories.

Automotive: Precision cuts for car seats, upholstery, and interior details.

Furniture: Large-scale cutting for leather furniture upholstery.

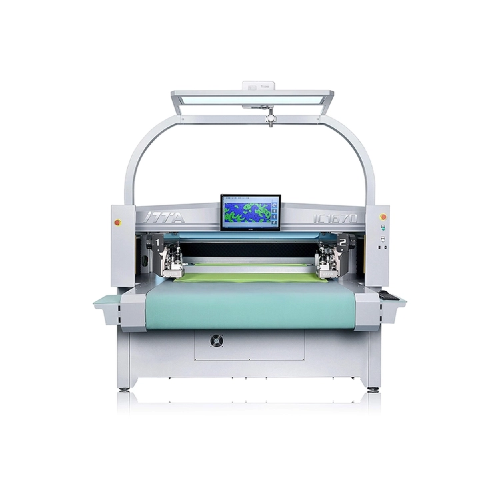

CNC (Computer Numerical Control) leather cutting machines are advanced, automated systems that use computer-controlled cutting paths to achieve precise cuts. These machines are highly customizable, allowing manufacturers to program specific patterns and shapes into the system.

Customization: CNC machines can handle highly complex designs, including intricate patterns and curves.

High Repeatability: Once programmed, CNC machines can repeatedly produce the same cut with high accuracy.

Automation: Reduces the need for manual labor, minimizing human error and increasing consistency.

CNC leather cutting machines are best suited for:

Luxury Fashion: Cutting complex designs for high-end leather goods.

Bespoke Leather Goods: Creating customized pieces for unique client orders.

High-Precision Industries: Automotive, aerospace, or any industry requiring precise cuts and shapes.

Semi-automatic leather cutting machines are a hybrid solution that combines manual input with automation. Operators manually position the leather, but the cutting process itself is automated, improving speed and consistency.

Advantages:

Lower upfront cost.

Simple operation, suitable for businesses with moderate production volumes.

Fully automatic leather cutting machines are highly advanced systems that require minimal manual intervention. These machines load, cut, and unload leather automatically, increasing production capacity and reducing human error.

Advantages:

High production efficiency.

Ideal for businesses with large-scale production.

Requires less labor input.

Selecting the right leather cutting machine involves more than just choosing the correct type. Several key features will influence your machine's performance, efficiency, and suitability for your manufacturing needs.

One of the first considerations when choosing a leather cutting machine is its cutting area. The size of the cutting bed will determine the maximum size of leather you can cut at once.

Machine Type | Cutting Area | Ideal For |

Small-Scale Leather Cutter | Up to 50 sheets/hour | Small businesses, bespoke products |

Medium-Scale Leather Cutter | 50-200 sheets/hour | Mid-sized manufacturers |

Industrial Leather Cutter | 200+ sheets/hour | Large-scale production |

The machine’s ability to handle different types of leather is crucial. Leather cutting machines should be capable of cutting various thicknesses, from thin fashion leather to thicker upholstery leather.

Soft Leather: Easy to cut with most machines.

Thick Leather: Requires a machine with higher cutting capacity and power.

Advanced leather cutting machines are equipped with nesting software that optimizes the placement of cut patterns on the leather. This software helps minimize material waste by efficiently arranging the patterns to maximize the use of each sheet.

Benefits: Reduced material waste, faster cutting, and better overall efficiency.

A user-friendly interface is essential for ensuring smooth operation. Look for machines with intuitive control systems that allow operators to easily adjust settings and monitor performance.

The durability of a leather cutting machine is crucial for long-term performance. Machines made from high-quality materials tend to be more reliable and have a longer lifespan.

Factors to consider: Look for machines made from sturdy materials that are resistant to wear and tear, such as high-grade steel.

Regular maintenance ensures the machine operates efficiently and lasts longer. Maintenance tasks may include:

Blade sharpening

Cleaning the machine

Software updates

The speed at which the leather cutting machine operates will directly affect your production rates. A faster cutting machine can help you meet tight deadlines and handle larger volumes of orders.

Considerations: Machines with higher cutting speeds are ideal for large-scale production, while smaller businesses may opt for slower, more affordable models.

One of the significant advantages of modern leather cutting machines is their ability to reduce material waste. Nesting software, combined with precise cutting, ensures that leather sheets are used as efficiently as possible.

When purchasing a leather cutting machine, it’s essential to consider the initial investment and weigh it against the long-term benefits. The ROI (Return on Investment) can vary depending on several factors, such as production volume, labor costs, and material savings.

Leather cutting machines can range from affordable, semi-automatic systems to high-end, fully automatic models. While the initial cost may be high, the efficiency gained in production speed, reduced labor, and minimized material waste can lead to substantial long-term savings.

Initial Cost: Semi-automatic machines may cost between $10,000 and $30,000, while fully automatic machines can range from $50,000 to $200,000 or more.

Long-Term Savings: By increasing production efficiency and reducing material waste, these machines can pay for themselves within a few years.

Investing in a leather cutting machine can have a profound economic impact on your business. With enhanced precision and faster production, your business can increase output while maintaining high product quality.

Case Studies: Manufacturers have reported up to 30% savings in material costs, as well as faster turnaround times on orders.

For businesses with limited capital, financing or leasing options can make purchasing a leather cutting machine more affordable. Many manufacturers offer flexible payment terms, allowing businesses to invest in cutting-edge technology without the burden of a large upfront cost.

Choosing the right leather cutting machine depends on a variety of factors specific to your business’s needs. Below are the key steps to help you make an informed decision.

For small businesses with lower production volumes, a semi-automatic machine may suffice. However, if you’re scaling up or managing large production runs, a fully automatic machine may be more appropriate.

Small Businesses: Semi-automatic machines are cost-effective and sufficient for lower volumes.

Large Manufacturers: Fully automatic machines are ideal for high-volume production.

Consider the types of leather you work with and the complexity of the cuts required. If you need to produce intricate designs or cut through thick leather, a CNC leather cutting machine might be the best option.

When choosing a leather cutting machine, it’s important to select a reputable manufacturer known for producing high-quality machines. Look for manufacturers that offer excellent after-sales support, including training, troubleshooting, and spare parts availability.

Before making a final decision, it’s a good idea to test the machine. Many manufacturers offer demos or trial periods, allowing you to assess whether the machine meets your needs in a real production environment.

Choosing the right leather cutting machine can have a profound impact on your business’s productivity, cost-effectiveness, and product quality. Whether you're a small business looking to expand or a large manufacturer aiming to optimize your production processes, understanding your specific needs and evaluating the right features is essential in making the best choice.

Investing in a high-quality leather cutting machine not only leads to significant long-term savings but also boosts efficiency and ensures superior product quality. These improvements will help your business maintain a competitive edge in a fast-paced market.

If you're looking to elevate your production capabilities and explore advanced cutting solutions, Guangdong ITTA Digital Intelligence Technology Co., LTD offers innovative machines designed to meet the diverse needs of businesses across industries. Their team can provide expert guidance and help you select the perfect leather cutting machine tailored to your requirements. Reach out today to learn more about their cutting-edge technology and how it can transform your business.

For small businesses, a semi-automatic machine with basic nesting software offers a good balance of cost, efficiency, and ease of use.

Consider the size and thickness of the leather you cut, as well as your production volume. For larger cuts or higher volumes, a machine with a larger cutting area and higher capacity will be needed.

Regular maintenance includes cleaning, blade sharpening, and software updates. Following the manufacturer’s guidelines ensures smooth operation.

Yes, many leather cutting machines are versatile and can cut various types of leather, from soft fashion leather to thicker upholstery leather, depending on the machine’s specifications.

Leather cutting machines can reduce material waste by up to 30% and increase production efficiency, leading to significant cost savings over time.