Views: 0 Author: Site Editor Publish Time: 2026-01-01 Origin: Site

In the fast-paced automotive interior industry, precision and efficiency in leather cutting are non-negotiable for producing high-quality automotive seats. Heavy-Duty Automotive Seat Leather Cutting Machines stand as essential tools for manufacturers, revolutionizing how leather materials are processed for automotiveseat covers, cushions, and related components. This article delves into the core features, working principles, and unmatched advantages of these specialized machines, showing how they elevate production standards while cutting costs.

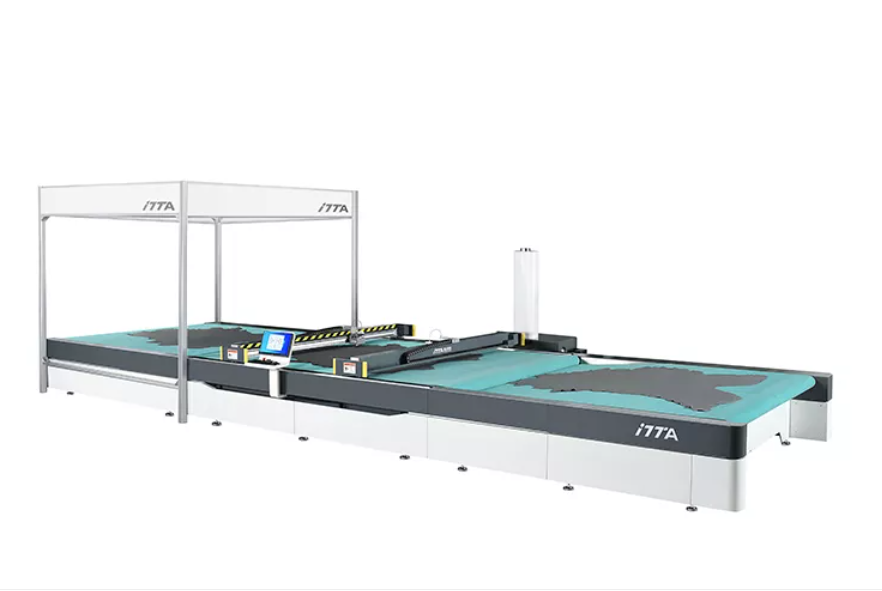

Heavy-Duty Automotive Seat Leather Cutting Machines are high-precision automated devices engineered specifically for cutting leather materials used in heavy-duty Automotive seat production. Unlike labor-intensive manual cutting—plagued by slow speeds, human error, and inconsistent results—these machines leverage advanced technology to deliver uniform, accurate cuts every time. Designed to handle the rigors of automotive manufacturing, they cater to the unique demands of heavy-duty Automotive seats, ensuring each piece meets strict fit and quality requirements.

Equipped with oscillating knife systems and CNC (Computer Numerical Control) technology, these machines achieve exceptional precision. The oscillating knife delivers smooth, fray-free cuts, critical for maintaining the aesthetic and functional integrity of automotive seat leather. CNC technology ensures cuts adhere to digital patterns with a tolerance of ±0.1mm, eliminating deviations that could compromise fit.

Tailored for heavy-duty Automotive seat applications, they handle a range of leather types:

| Leather Type | Characteristics | Cutting Technology Used |

|---|---|---|

| Genuine Leather | Durable, natural texture (ideal for premium heavy-duty Automotive seats) | Oscillating Knife Cutting |

| Synthetic Leather | Cost-effective, wear-resistant (suited for high-use seats) | Oscillating Knife Cutting |

| Eco-Leather | Sustainable, durable (meets modern automotive standards) | Oscillating Knife Cutting |

Integrated nesting software optimizes pattern placement on leather hides, minimizing waste and maximizing material utilization—up to 15% more efficient than traditional methods. This is especially valuable for heavy-duty Automotive seat production, where leather costs are significant.

A vacuum adsorption platform keeps leather securely in place during cutting, preventing shifts that cause errors. Pre-cut scanning technology detects defects (wrinkles, scars, holes) and measures leather thickness, ensuring only high-quality material is used and adjusting the blade for consistent results across varying thicknesses.

Automated adherence to CAD-uploaded patterns ensures every cut matches exact specifications, critical for heavy-duty Automotive seats where fit directly impacts comfort and safety. Eliminates human error from manual cutting, delivering uniform quality across high-volume production runs.

Automation allows simultaneous cutting of multiple pieces, increasing production speed by up to 50% compared to manual methods. This enables manufacturers to meet tight deadlines for heavy-duty Automotive seat orders without sacrificing quality, while reducing labor costs by freeing workers for value-added tasks (assembly, quality control).

Intelligent nesting software reduces material waste, cutting raw material costs for heavy-duty Automotive seat production. Combined with lower labor expenses and minimal downtime, these machines deliver strong long-term ROI—offsetting initial investment quickly.

Material Preparation: Leather hides are placed on the machine’s bed and secured by the vacuum adsorption platform to prevent movement.

Smart Scanning: The machine scans the hide to detect defects and measure thickness, adjusting cutting parameters accordingly.

CNC-Powered Cutting: Pre-programmed digital patterns (for heavy-duty Automotive seat components) are executed via CNC technology, with the oscillating knife delivering precise, clean cuts.

Finished Output: Cut pieces are ready for assembly, requiring minimal finishing work thanks to smooth edges.

Evaluate Production Volume: Opt for robust heavy-duty models for high-volume manufacturing; entry-level automated machines suit small workshops or low-volume runs.

Check Material & Design Compatibility: Ensure the machine handles the leather types (genuine, synthetic, eco) and complex patterns used in your heavy-duty Automotive seat designs.

Prioritize Software Integration: Choose machines compatible with CAD software for seamless pattern updates and intelligent nesting capabilities.

Balance Budget & ROI: Consider long-term savings (reduced labor/material costs) over initial price—heavy-duty models offer greater value for scaling production.

Leverage Automation: Let machines handle cutting autonomously, allowing teams to focus on heavy-duty Automotive seat assembly and quality control.

Maximize Material Use: Rely on nesting software to minimize waste, aligning with sustainable manufacturing practices.

Regular Maintenance: Schedule blade replacements and software updates to keep the machine operating at peak performance, extending its lifespan and avoiding costly downtime.

Investing in a Heavy-Duty Automotive Seat Leather Cutter can transform operations in the automotive interior industry. These machines provide superior precision, reduce material waste, and significantly improve production efficiency. By automating the leather cutting process, businesses can focus more on quality control and assembly, reducing labor costs and improving ROI.

Whether you're a small workshop or a large-scale manufacturer, the right Leather Cutting Machine can greatly enhance productivity, reduce costs, and ensure top-quality results. ITTA offers cutting-edge products that provide exceptional value, helping businesses optimize their production processes and achieve greater profitability.

A: A Heavy-Duty Automotive Seat Leather Cutter is a high-precision machine used for cutting leather materials used in automotive interiors. It automates the cutting process, ensuring fast, accurate, and clean cuts for Automotive seat covers, door panels, and more.

A: A Leather Cutting Machine uses advanced cutting technologies like oscillating knives and CNC systems to cut leather precisely. It follows digital patterns, ensuring accuracy while reducing material waste and increasing production efficiency.

A: A Automotive seat leather cutting machine improves production efficiency, reduces material waste, and ensures high-quality, consistent cuts. It automates the process, cutting down labor costs and meeting tight production deadlines.

A: Yes, a Leather Cutting Machine can handle various leather types, including genuine leather, synthetic leather, and eco-friendly options. It adapts to different thicknesses, ensuring smooth cuts for all materials.

A: The price of a Heavy-Duty Automotive Seat Leather Cutter varies based on the machine's capabilities and features. Investing in such machines offers long-term savings through reduced labor and material costs, improving ROI.